|

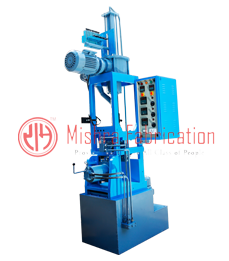

| Technical Specification |

| INJECTION UNIT |

|

Diameter of Screw |

55 mm |

|

Maximum Shot Capacity |

600 Grms. |

|

Plasticizing Capacity |

60 Kgs/hr |

|

Stock of Screw |

230 mm |

|

Number of Screw Rotation |

210 r.p.m. |

|

Absolute Injection Pressure |

11.0 m/t |

|

Specific Injection Pressure |

400 Kgs/cm2 |

| |

| Mould Clamping Unit |

|

Clamping Pressure |

23m/t |

|

Clamping Stroke |

100 mm |

|

Maximum Mould Size (LxWxH) |

300 X 200 X 225mm |

| |

|

|

| ELECTRICAL EQUIPMENTS |

|

Motor for drive of oil pump |

7.5 H.P. |

|

Motor for driving Plasticizing Screw |

7.5 H.P. |

|

Heating Capacity |

3.25 K.W. |

|

Heating Control (Pyrometer) |

3 No. |

|

(Sunvik) |

3 Nos. |

| |

|

|

| HYDRAULIC EQUIPMENTS |

|

Hydraulic Pump |

62 Litres/mm |

|

Pump Pressure |

120 Kgs/cm2 |

| |

|

|

| GENERAL |

|

Floor area of machine |

750 mm X 1150 mm |

|

Weight of Machine |

Monted on Machine |